Rand Snijblad voor Microkristal Steen

Productoverzicht

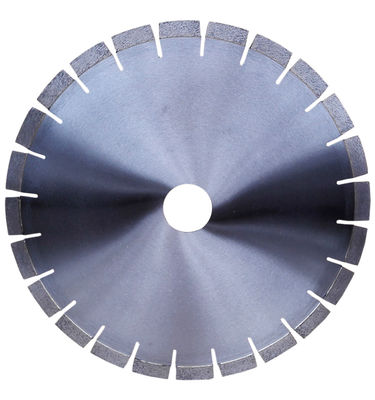

Ervaar precisie snijden voor premium microkristallijne steenmaterialen met onze gespecialiseerde Rand Snijblad voor Microkristal Steen. Speciaal ontworpen voor de unieke eigenschappen van microkristalsteen (ook bekend als gekristalliseerd glas of nano-gekristalliseerde steen), leveren deze professionele diamantbladen ideale randafwerking met superieure bladcontinuïteit en zorgen ze voor spaanderloze resultaten aan beide zijden van de snede.

Technische Specificaties

| Productnaam |

Diameter (mm) |

Stalen Kern (mm) |

Segment Afmeting (mm) |

Segment Aantal |

Toepassing |

| Rand Snijblad voor Microkristal |

300 |

2.2 |

43/41*2.8*10 |

22 |

Microkristal Steen |

|

350 |

2.2 |

43/41*3.2*10 |

25 |

|

400 |

2.4 |

43/41*3.6*10 |

29 |

Product Hoogtepunten

1. Ideale Randafwerking met Betere Bladcontinuïteit

- Microkristal-Specifiek Ontwerp: Geoptimaliseerd voor de glas-keramische composietstructuur

- Continue Rand Technologie: Naadloze diamantrand zorgt voor ultra-gladde sneden

- Verbeterde Bladcontinuïteit: Uniforme diamantverdeling voorkomt snijonderbrekingen

- Minimaal Materiaalverlies: Ultra-dun bladprofiel maximaliseert materiaalgebruik

2. Betere Snijscherpte en Afwerkingsefficiëntie, Geen Spaanders aan Beide Kanten

- Premium Diamantkorrel: Hoogwaardige diamantdeeltjes voor snel, schoon snijden

- Geavanceerde Bindingsmatrix: Speciaal geformuleerd voor microkristallijne steeneigenschappen

- Anti-Spaander Technologie: Speciaal randontwerp voorkomt in- en uittreden van spaanders

- Verbeterde Snijsnelheid: 30-45% sneller dan standaard steensnijbladen

- Dubbelzijdige Bescherming: Zorgt voor schone sneden op zowel de boven- als onderkant

Veelgestelde Vragen

V: Wat maakt microkristallijne steen anders dan gewone steen?

A: Microkristallijne steen is een glas-keramische composiet met unieke eigenschappen - het is harder dan marmer maar brozer dan graniet, waardoor gespecialiseerde snijgereedschappen met fijnere diamantkorrel en zachtere bindingsmatrices nodig zijn.

V: Kunnen deze bladen andere soorten steen snijden naast microkristalsteen?

A: Hoewel geoptimaliseerd voor microkristallijne steen, werken onze bladen goed op marmer, zacht graniet en kunststeen. We raden echter materiaal-specifieke bladen aan voor optimale resultaten op verschillende soorten steen.

V: Hoe voorkom ik spaanders bij het snijden van microkristallijne steen?

A: Gebruik continue randbladen, behoud de juiste snijsnelheid, zorg voor voldoende waterkoeling, ondersteun het materiaal volledig en gebruik ons anti-spaander bladontwerp voor de beste resultaten.

V: Wat is het verschil tussen de standaard en ultra-fijne serie?

A: De ultra-fijne serie gebruikt fijnere diamantkorrel (80/100-100/120) voor premium randkwaliteit, terwijl de standaard serie sneller snijden biedt met een goede randkwaliteit voor algemeen fabricagewerk.

V: Moet ik water gebruiken bij het snijden van microkristallijne steen?

A: Nat snijden wordt sterk aanbevolen - het voorkomt thermische schokken, vermindert het risico op spaanders, verlengt de levensduur van het blad en zorgt voor de schoonste sneden op dit temperatuurgevoelige materiaal.

Bestelproces

- Aanvraag: Dien vereisten in (materiaaldikte, bladgrootte, hoeveelheid)

- Technische Consultatie: Expert aanbevelingen voor optimale selectie

- Offerte: Gedetailleerde prijsopgave binnen een week

- Monsterbestelling: Test producten (optioneel)

- Orderbevestiging: Onderteken aankoopovereenkomst

- Productie: Productie met kwaliteitscontrole

- Inspectie: Eindtest en verpakking

- Verzending: Levering volgens overeengekomen voorwaarden

- After-sales: Voortdurende technische ondersteuning

Klaar om perfecte microkristallijne steenranden te bereiken?

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!